Prospects of Industrial Waste Heat Integrated Torrefied Wood Pellet Supply Chain in Sri Lanka

By Eng. (Dr.) Duleeka Sandamali Gunarathne

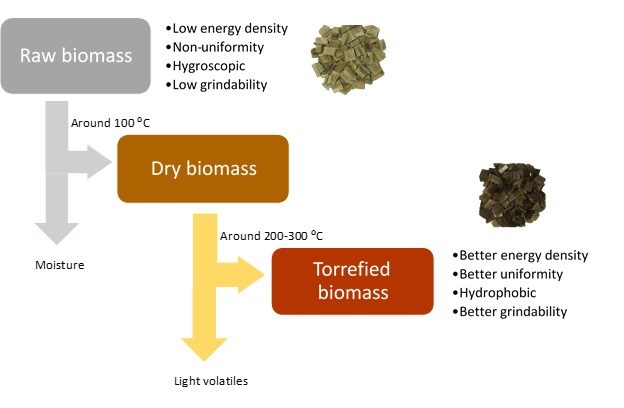

Biomass is the main industrial heat source in Sri Lanka. However, the effective utilization of biomass as a renewable energy source is hindered by several pitfalls namely low energy density, non-uniformity, hygroscopic nature, and low grindability which are difficult to be properly managed by yet common pretreatment technologies like milling, drying, and pelletizing. Torrefaction is a thermochemical pretreatment method that results in hydrophobic, easily grindable, energy densified, and uniform biomass (Figure 1).

Figure 1: Schematic representation of torrefaction process

Figure 1: Schematic representation of torrefaction process

The torrefaction process is typically carried out at 200-300 ⁰C for a duration of up to one hour in an inert atmosphere such as nitrogen. However, large-scale use of inert gas is neither realistic nor economical. When it comes to an economical heat source, the waste heat available in the industrial flue gas streams at the same temperature range is best suited as a torrefaction medium. Flue gas generally contains 2-6% oxygen which provides a slightly oxidative atmosphere instead of the inert atmosphere expected in the torrefaction process. However, the oxidative atmosphere provides the possibility of torrefaction at lower temperatures and this extends the application opportunities even when the flue gas temperature is somewhat low. There are temperature-specific limits beyond which an increase in oxygen concentration leads to an oxidative thermal runaway. At a high torrefaction temperature, woody biomass shows higher resistance against oxidation torrefaction than fibrous biomass. Therefore, woody biomass types are more suitable for torrefaction in the oxidative environment and Gliricidia can be a potential candidate.

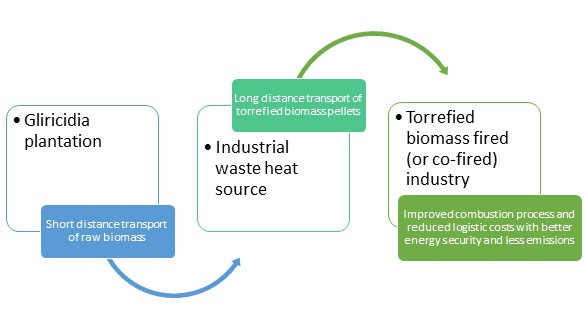

In 2005, Gliricidia (Gliricidia sepium) was introduced as the fourth plantation crop in Sri Lanka after Tea, Coconut, and Rubber. This plant has good energy crop characteristics such as fast-growing rate, adaptability to any weather conditions, free from pests and diseases as well as suitability for intercropping. Statistics of national land usage indicate that more than 1,700,000 ha of land is unproductive and abandoned, mostly in the dry zone in Sri Lanka and these areas can be used for the plantation of energy crops like Gliricidia in addition to intercropping. A country like Sri Lanka, having no fossil fuel reserves, but having numerous biomass resource potential can benefit from this technology in several ways both in torrefied pellet production and application as illustrated in Figure 2.

There are industries in Sri Lanka with flue gas temperatures suitable for the torrefaction process and these industries have a good opportunity to recover this waste heat through the integrated torrefaction process. Torrefied wood pellets can be considered as a value-added product and in addition to financial gain, the diversification of the business makes these local industries more resilient. A good torrefied biomass pellet supply chain can be developed by utilizing industrial flue gas as the heat source for the torrefaction process.

Industries with biomass-fueled dryers, heaters, boilers, and furnaces can also benefit by using torrefied biomass due to improved combustion process and reduction of logistic costs. The transport cost is reduced due to improved energy density and storage cost is reduced due to hydrophobicity which makes open-air storage is feasible. Further, grindability is also improved by torrefaction making it easy to preprocess.

In addition, the torrefied biomass; a coal-like material, can be used for co-firing in coal-fired power plants to reduce the environmental damage caused by coal. Lakvijaya coal power plant at Norochcholai is the main power producer in Sri Lanka adding 900 MW to the national grid. Since Sri Lanka does not have coal reserves, the coal requirement has to be met through imports. Substituting a part of coal with torrefied biomass may not only improve energy security and reduce emissions but also economically favorable if properly implemented with a good torrefied biomass supply chain. Industry participation and government intervention are crucial factors for such an initiative.

Figure 2: The concept of torrefied Gliricidia supply chain

Figure 2: The concept of torrefied Gliricidia supply chain

Eng. (Dr.) Duleeka Sandamali Gunarathne is a Senior Lecturer (Grade II) in the Department of Chemical and Process Engineering, University of Moratuwa. She has earned her first degree in Chemical and Process Engineering from the University of Moratuwa in 2007 and then, MSc in Sustainable Energy Engineering in 2012 and PhD in the field of Energy and Furnace Technology in 2016 from Royal Institute of Technology (KTH), Sweden

Eng. (Dr.) Duleeka Sandamali Gunarathne is a Senior Lecturer (Grade II) in the Department of Chemical and Process Engineering, University of Moratuwa. She has earned her first degree in Chemical and Process Engineering from the University of Moratuwa in 2007 and then, MSc in Sustainable Energy Engineering in 2012 and PhD in the field of Energy and Furnace Technology in 2016 from Royal Institute of Technology (KTH), Sweden